Subaqueous in-pit disposal

Henna Punkkinen, Markku Juvankoski, Tommi Kaartinen, Jutta Laine-Ylijoki, Elina Merta, Ulla-Maija Mroueh, Jarno Mäkinen, Emma Niemeläinen & Margareta Wahlström, VTT Technical Research Centre of Finland Ltd, P.O. Box 1000, FI-02044 VTT, Finland.

Introduction

A placement of sulphide containing mine wastes under permanent water cover is demonstrated to be one of the most effective ways for preventing acid mine drainage (AMD) generation as water efficiently inhibits the oxidation of sulphides (Steffen Robertson and Kirsten Inc. 1989, Tremblay & Hogan 2001, INAP 2009). The maximum concentration of dissolved oxygen in water is around 30 times less than in the atmosphere, and even more importantly, the transfer of oxygen trough water is very limited as it can be almost 10,000 times slower than similar diffusive transfers in the air; the factors that considerably diminish the rate of acid generation and metal dissolution in subaqueous conditions (Tremblay & Hogan 2001). In addition, metal hydroxide precipitation, sulphide reduction by bacteria, and development of inhibiting sediment layers between the interaction of tailings and water comprise other favourable implications associated with the use of water covers (INAP 2009).

The disposal of wastes into natural waters, man-made impoundments, mined out flooded underground mine spaces or open pits are examples of the various ways in which water covers can be achieved (Steffen Robertson and Kirsten Inc. 1989, ITRC 2010). This chapter focuses on the subaqueous disposal of solid mine wastes into closed mine pits (backfilling). There are two different subaqueous variations that can be used; underwater disposal option and elevated water tables option (MEND 1995).

Backfilling is not automatically a good choice for mine waste management (MEND 1995) and site-specific factors should always be carefully considered when weighing up the suitability of this disposal option, as the applicability of the method is very dependent on the mine site characteristics (MEND 1995, ITRC 2010). Although the method has been widely used internationally for a long time, backfilling has not always been a conscious environmental decision, but rather a matter of convenience. However, nowadays subaqueous in-pit disposal has become an increasingly considered option for environmentally acceptable permanent disposal of sulphide containing mining wastes. (MEND 1995)

Other Closedure web pages related to the use of backfill method include:

- Underwater disposal in underground mines (during mine operation)

- Disposal in underground mine (during mine closure)

- Disposal in underground mine under the water level (during mine closure)

- Backfilling in water management

Description of the methodology

In the subaqueous backfilling method waste is disposed into the closed pit covered with water, or in the section of the open pit where mining has ceased. The water cover forms naturally as a mixture of bedrock groundwater and rainwater and will remain the backfilled waste material water-covered, or a wet cover containing non-acid generating till layer and water is constructed (Figure 1). (Kauppila et al. 2013) Flooding can also be used to cover the backfilled waste material (MEND 1995). A protective layer between waste filling and bedrock can be placed to mitigate groundwater contamination (Kauppila et al. 2013). Reducing the hydraulic gradient to near zero across the pit or making diffusion the main transport mechanism are ways to constrain convective outflow and diminish contaminant release potential (MEND 1995).

Figure 1. Waste rocks (with/without tailings blended) backfilled into the open pit under water cover. Till is used to cover shallow water areas. (adapted from Kauppila et al. 2013)

Backfilling practices are well developed. An extensive MEND report 2.36.1 “Review of in-pit disposal practices for the prevention of acid mine drainage – Case studies” presents the following subaqueous pit disposal concepts (MEND 1995):

- Underwater disposal: A pit lake or wetland is situated upon the backfilling. Method can be divided into four sub-categories:

- Simple underwater disposal. Most commonly applied subaqueous disposal option, where wastes are placed at the bottom of the pit under water. Water quality and quantity need to be taken into consideration. Other underwater disposal concepts can be considered if this option is not suitable.

- Underwater disposal with surface barrier. A barrier reduces contaminant transport from waste to water because fine-grained material acts as a diffusion control. Clean soil (sand, clay, till etc.) is often used to cover wastes. An optimal barrier thickness can be determined by using numerical models.

- Underwater disposal with groundwater barrier. Used if there is a risk of a substantial convective flow of groundwater through the waste disposal. Three different barrier types exist, however, these options tend to be costly and only few applications exist.

- Underwater disposal with surface and groundwater barriers. A combination of the two previous options.

The underwater disposal concepts are illustrated in Figure 2.

Figure 2. Pit disposal concepts (adapted from MEND 1995).

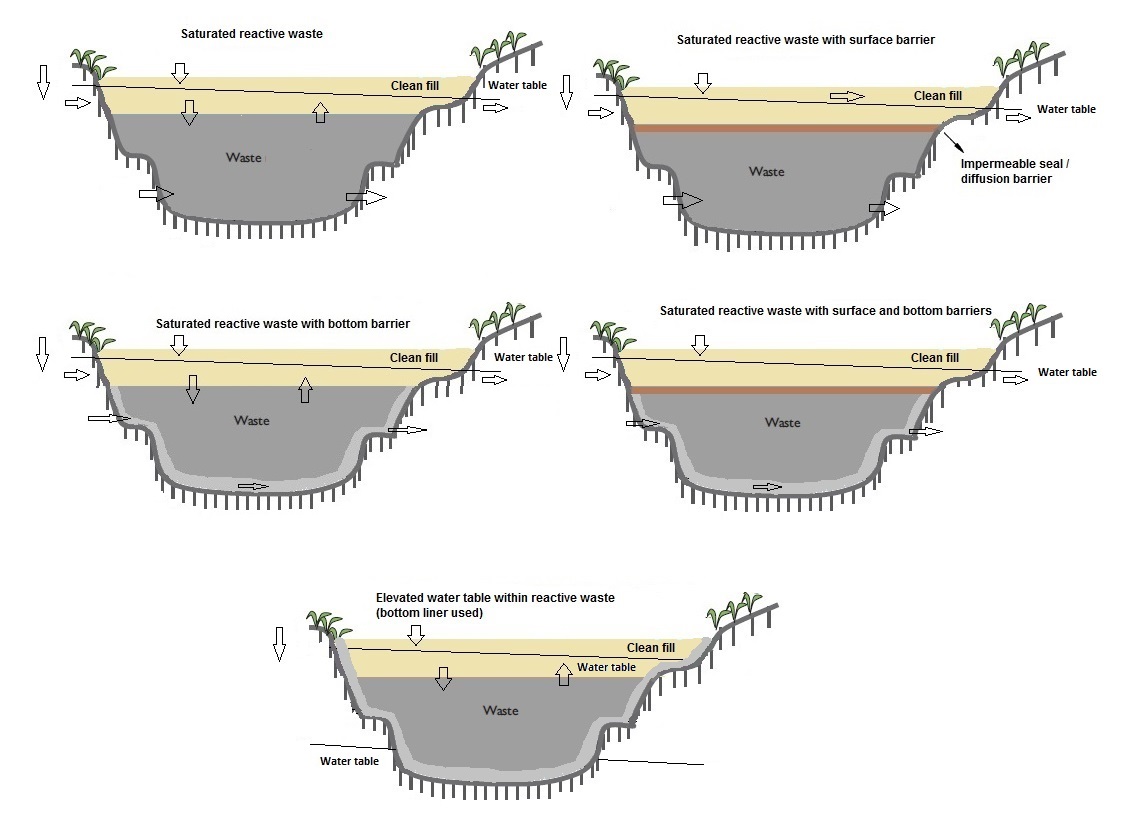

- Elevated water tables: The pit is backfilled near to the original ground surface. The aim is to prevent oxidation by raising the water table above the waste into a layer of clean fill. The main difference between the two disposal methods is that in the elevated water concept the water table is usually sloped causing water to infiltrate through waste material similar to groundwater, unless control barriers are placed around the waste. The options for the elevated water tables include:

- Saturated reactive waste. Analogous to the simple underwater disposal option.

- Saturated reactive waste with surface barrier. Analogous to the underwater disposal option with surface barrier. Surface barrier in underwater disposal concepts is typically a diffusion barrier, but in this option an infiltration barrier can also be a potential choice, as it would inhibit convective groundwater flow by preventing rainwater infiltration. The barrier can either be a low permeability layer or a pervious layer.

- Saturated reactive waste with bottom barrier. Analogous to the underwater disposal option with groundwater barrier. Suitable for wastes having a low permeability as the option uses of pervious surround.

- Saturated reactive waste with surface and bottom barriers. Analogous to the underwater disposal option with surface and groundwater barriers. Suitable for wastes having a low permeability as the option uses of pervious surround.

- Elevated water table within reactive wastes using a bottom liner. An impermeable bottom liner can be used in areas where groundwater table is depressed. Bottom layer prevents infiltrated water to leave the waste and forms a basin with elevated water table. However, if waste material has a permeability that is low enough bottom barriers are not necessarily needed, as material itself may be able to form an elevated water table.

The elevated water table concepts are illustrated in Figure 3.

Figure 3. Elevated water table concepts (adapted from MEND 1995).

MEND manual 2.36.1 presents 12 case studies related to in-pit disposal (MEND 1995):

- Underwater disposal: Collins Bay B-Zone, Saskatchewan, Canada; Island Copper, British Columbia, Canada; Udden, Sweden

- Underwater disposal with alkaline blending: Owl Creek, Ontario, Canada

- Underwater disposal with groundwater barriers: Rabbit Lake, Saskatchewan, Canada

- Underwater disposal with top barrier: Solbec, Québec, Canada; Stratapound CNE, New Brunswick, Canada; Deilmann, Saskatchewan, Canada

- No waste disposed – flooded pit studies: Robinson, Nevada, U.S.A.; Gunnar, Saskatchewan, Canada; Cluff “D”, Saskatchewan, Canada; Berkeley, Montana, U.S.A.

In addition, the report identifies 13 underwater disposal sites and two elevated water table examples, and lists altogether over 60 sites using in-pit disposal practices (water or dry covers), mainly located in the US and Canada.

Appropriate applications

The subaqueous in-pit disposal is a suitable method for both acid generating and non-acid generating solid mining (ITRC 2010). More exact, Kauppila et al. (2013) present the open-pit backfilling method to be suitable for waste rocks (for both acid generating and non-acid generating) and for neutralising tailings blended or layered in with the waste rocks (Kauppila et al. 2013). The hydrogeology of the pit and the surrounding area will play an important role when assessing the applicability of the method. Bedrock having low permeability, minimal or no groundwater gradient across the mine workings, and no significant fracture zones or faults, would offer a perfect environment for a disposal of acid generating wastes. As these ideal characteristics are only seldom achievable other desirable features include minor groundwater inflows (ending in an insignificant downstream environmental impact), acid neutralising capacity of the surrounding rocks, and geochemical characteristics that reduce the spreading of the contaminants into the surrounding environment. (Tremblay & Hogan 2001) If there is a possibility that acidic seepage from pit wall mineralization along fractures, joints, faults and pit walls may occur, this may impact on the applicability of the method (Tremblay & Hogan 2001) and other disposal activities should be used (Kauppila et al. 2013).

Not only is important to remember that not all pits are necessarily appropriate for backfilling (Lottermoser 2007), but the subaqueous disposal of wastes itself may be challenging (Tremblay & Hogan 2001). For example, when considering the deposition of old partially or completely oxidised sulphidic wastes under water it must be taken into account that soluble secondary minerals may dissolve and potentially release metals, metalloids, and salts to the water. In fact, it is recommended that these kinds of wastes should not be deposited under water at all. (Lottermoser 2007)

In general, wet cover methods should not be used in arid or semi-arid regions, as in the case of subaqueous disposal it is important to reach a stable anoxic state and maintain a water saturation level that will remain continuous and complete. In arid and semi-arid climates deep water bodies are not common and year-round supply of water is not granted; the two factors that would ensure the waste material to remain permanently saturated and prevent AMD (acid mine drainage) formation (Lottermoser 2007). Also a threat of seismic events, severe storms, and the stability issues related to the water cover maintaining in the long term etc. may hinder the usability of the method (MEND 1995).

Table 1 presents advantages and disadvantages associated with the use of subaqueous in-pit disposal method.

Table 1. Advantages and disadvantages of subaqueous in-pit disposal (Steffen Robertson and Kirsten Inc. 1989, MEND 1995, Lottermoser 2007, ITRC 2010).

| Advantages | Disadvantages |

| High waste volumes can be treated | Possible future use of the ore body becomes more difficult |

| Offers a permanent disposal option for mining wastes | If the technology is implemented as a remedial action, wastes have to be stored elsewhere when mining is underway and after the mining has ceased material needs to be moved back |

| Mine waste can be placed back to its original geochemical environment | Lack of detailed monitoring data for backfilled pits has been a major disadvantage; although waste backfilling to the mine workings seems to be a widely used method, only few mine sites have been carefully monitored during the previous years |

| Generation and release of contaminants reduced, most contaminants can be treated. An effective control of sulphide bearing wastes | Sulphides in the pit walls above the final water elevation table can oxidise and cause water quality deterioration, if no prohibitive actions are made |

| Prevents dusting | May cause environmental concerns such as groundwater contamination |

| Flexible applications | Regulatory restrictions concerning subaqueous disposal |

| Costs savings in comparison to many other methods, especially when calculating the “total” costs for waste management actions | The swell factor of reactive wastes may lead to the situation where the volume of waste is larger than the deposition pit, especially as it is probable that the mine pit will flood to a point less than full |

| Long term erosional / geomorphological concerns diminished: retaining walls not needed -> no risk for the embankment stability, waste placement is a part of a stabilization plan of the mine workings | |

| The risk of exposure through direct contact and accidental releases is diminished | |

| Quite easily implemented | |

| Future land use controls for the mine site can possibly be eliminated | |

| Less long-term maintenance and monitoring needed |

Performance

Many same aspects that are related to wet cover methods in general are also applied to subaqueous in-pit backfilling method. The waste treatment capacity of the method is good, as high waste volumes can be deposited (ITRC 2010). However, the swell factor of reactive waste is commonly around 30% and this may cause a situation where there is a larger volume of waste to be deposited than originally mined, especially as it is probable that the mine pit will flood to a point less than full (Steffen Robertson and Kirsten Inc. 1989).

The simplest way to perform the backfilling is to use pit ramps, but also end-dumping over the edge may become in question. The most harmful wastes should be placed appropriately below water table, or layer/mix with acid neutralizing materials. (MEND 1995) The risk for groundwater contamination can be reduced by filling the gaps between waste and rock walls with fine-grained rock powder or sulphide-free tailings. (Kauppila et al. 2013)

Environmental concerns may arise for example if the walls of the workings fracture, as the oxidised groundwater may be able to penetrate to the pit and accelerate oxidation. Although some concerns related to subaqueous disposal and backfilling exist, there are also examples of the cases where in-pit disposal has led to environmental improvements, as the acid generation and metal leaching from the waste rock piles located on the ground can be reduced and better observed trough underwater deposition (MEND 1995).

Costs for the method are site specific and depend on the selected disposal concept (Tremblay & Hogan 2001). However, general cost estimates for the in-pit disposal options (both dry and wet cover methods) are given by Tremblay & Hogan (2001). They assess the unit costs for waste rock disposal to be between $1 and $2 / waste tonne, and for tailings $1 and $3 /waste tonne, without including site specific factors. (Tremblay & Hogan 2001)

Design requirements

Water cover methods require adjusting of the water level, and a construction of overflow channels or water discharge pipes. In the case of water quality deterioration, an active or passive treatment must be performed. (Kauppila et al. 2013) A sufficiently thick water layer should be used in underwater disposal to assure that the waste will remain water covered. The size of the area to be covered together with the wind conditions causing vertical blending of water will have an influence of the required water layer thickness. However, the water blending can be prevented using underwater ridges covered with till. If the water depth is not deep enough, a surface barrier can be used to cover the waste. (Kauppila et al. 2013) Also the effects of cold climate should be taken into consideration in Nordic countries. Continuous revision of the original deposition plan, together with field studies and thermal modelling are important in regions where freezing occurs at regular intervals. (MEND 1995)

As mentioned earlier, the applicability of the method is strongly dependent on site-specific conditions, and it is important to remember that not all pits are necessarily appropriate for backfilling (Lottermoser 2007). Also the nature and extent of technical studies, controlling, and maintenance needed will differ site specifically (MEND 1995). Although subaqueous deposition of wastes into the old mine workings has been widely used earlier, not until recently the proper designing and the environmental acceptability issues of the method have been more closely perceived. A careful examination of several factors, taking also account of both the short and long term effects, is essential when assessing the suitablility of the method for the certain mine site and choosing the appropriate concept for use. (Table 2) All presented concepts for in-pit disposal are generally well developed, and although several requirements and site characterisation issues have to be considered and determined during the planning and designing phase these aspects can be nowadays reasonable well assessed. (MEND 1995)

Table 2. Considerations regarding to an applicability of subaqueous in-pit disposal method (Steffen Robertson and Kirsten Inc. 1989, MEND 1995, Tremblay & Hogan 2001, INAP 2009, ITRC 2010).

| Water related issues and requirements | Waste related issues and requirements | Issues and requirements related to pits, walls and their stability | Environmental and health aspects | Other issues |

|

|

|

|

|

References

INAP 2009. The GARD Guide. The Global Acid Rock Drainage Guide. The International Network for Acid Prevention (INAP). http://www.gardguide.com

ITRC (Interstate Technology & Regulatory Council) 2010. Backfilling and Subaqueous Disposal. Washington, D.C.: Interstate Technology & Regulatory Council, Mining Waste Team.

Kauppila, P., Räisänen, M. L. & Myllyoja, S. 2013. Best Environmental Practices in Metal Ore Mining. Finnish Environment 29 en/2013.

Lottermoser, B.G. 2007. Mine Wastes: Characterization, Treatment and Environmental Impacts, 2nd Edition. Springer, Berlin.

MEND 1995. Review of In-pit Disposal Practices for the Prevention of Acid Drainage – Case Studies. MEND Report 2.36.1.

Steffen Robertson and Kirsten Inc. 1989. Draft Acid Rock Drainage Technical Guide, Volume 1. British Columbia Acid Mine Drainage Task Force Report.

Tremblay, G.A. & Hogan, C.M. 2001. MEND Manual, Volume 4. Prevention and Control. MEND Report 5.4.2d.

Leave A Comment

You must be logged in to post a comment.