Dams

Emma Niemeläinen, Markku Juvankoski, Tommi Kaartinen, Jutta Laine-Ylijoki, Elina Merta, Ulla-Maija Mroueh, Jarno Mäkinen, Henna Punkkinen & Margareta Wahlström, VTT Technical Research Centre of Finland Ltd, P.O. Box 1000, FI-02044 VTT, FINLAND.

Water management: Dams at mine closure phase

Introduction

Dams are essential for water and tailings management at the mine site. Dams control and retain the movement of water, and act as a waste disposal area of slurried tailings. (European Commission 2009, Kauppila et al. 2013) There may be several dam, impoundment and barrier structures at a single site, and these structures may differ depending on their function, materials available, and site specific circumstances and needs. Dams are constructed either on the flat land, existing mine pit or valley formation. (European Commission 2009) Dam construction materials contain mostly soil, gravel, and clay or till in the confining bed. Due to their availability and low costs, also coarse tailings or waste rock may be used. Sometimes also concrete may be used (Kauppila et al. 2013). The height of the embankments may be over 30 meters, and their length tens of meters (Vanden Berghe et al. 2011).

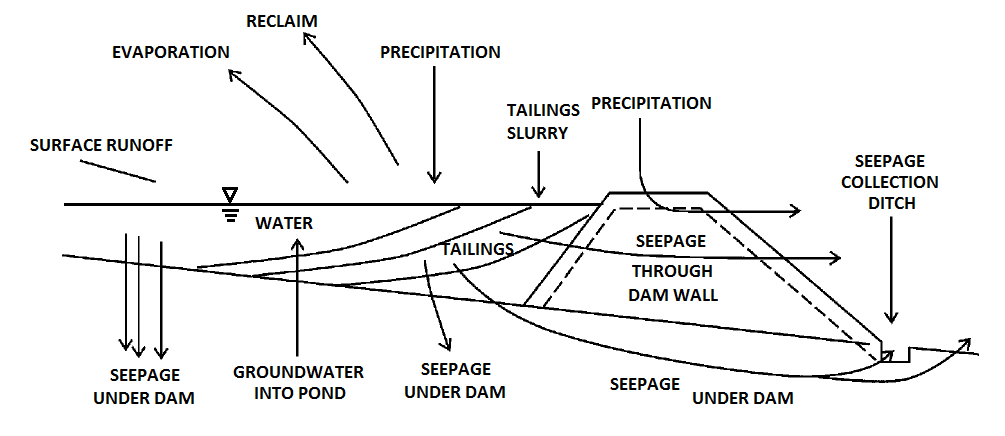

This article emphasizes the tailings dams, because they are common at mine sites and on the other hand they differ remarkably from the conventional dams. The most important differences between the conventional and the tailings dam concern their construction, service lives and often also materials used (Martin & Davies 2000, ICOLD 1996a). The tailings dam is constructed in several stages that can last over decades and the final stability may be achieved only at the mine closure phase. The planned design life of the mine dam may be a hundred years (Kauppila et al. 2013, ICOLD 2013). Figure 1 presents an example of a typical tailings dam, and a water cycle of the system.

Figure 1. A dam water cycle (modified after European Commission 2009).

The best result is achieved when the mine closure phase is kept in mind already during the dam design and construction phase. However, when the mine life cycle reaches the closure phase, dam rehabilitation might be needed. Rehabilitation measures contain e.g. formation of the embankment slopes and edges, stabilizing, landscaping, routing the surface and precipitation waters, lowering the pore pressure, pumping, draining, and checking the functionality of existing structures and/or demolition. Also chemical aspects of the tailings deposit and alteration must be taken into account. The aim is to get the dam environmentally as safe and stabile as possible: “[tailings] dams and its contents should be left in a condition which will permanently withstand natural forces and not cause ongoing harm to the environment” (ICOLD 2013). Regular monitoring is essential during the operational, as well as during the post closure phase (ICOLD 1996b, 2013; Heikkinen et al. 2008, Kauppila et al. 2013).

Description of the technology

There are several different dam types depending on the purpose, circumstances and other factors. A dam needs to be resistant to physical damages and restrict the pollution of the surrounding area. The tailings material is conveyed as slurry and discharged to the pond. There are several discharging/deposition methods, for example conical, doughnut-style or one point spigotting can be used. Discharging/deposition method used effects to the distribution and settling of the material depending on the grain size and the water content; larger sized particles settle near to the discharge point, whereas the finer grains suspend further off. Often the tailings are discharged straight from the embankment of the impoundment, leading to the settling of coarser material immediately after the edge. These coarser tailings can support the dam structure or can be used as a raising material of the dam itself. (Kauppila et al. 2013) The excess water which usually ponds into the impoundment is e.g. pumped out, evaporated, treated and reused, or left to form a water cover if the tailings material is acid generating (European Commission 2009).

Confining dam types are typically classified as follows (ICOLD 1996c, European Commission 2009):

- Non-permeable dams (water retention type)

- Permeable dams

Non-permeable dams (water-retention type)

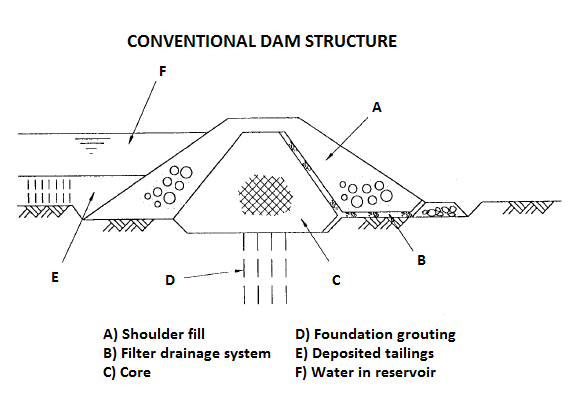

A conventional dam is completely built before the deposition of waste begins. Conventional dam has a compacted core and shoulders which protect the core from the erosion; it is similar to the confine water dams. A dam structure may contain drainage and filtration systems for seepage water (Figure 2). (ICOLD 1996c, European Commission 2009)

Figure 2. A conventional dam structure (modified after ICOLD 1996c, European Commission 2009).

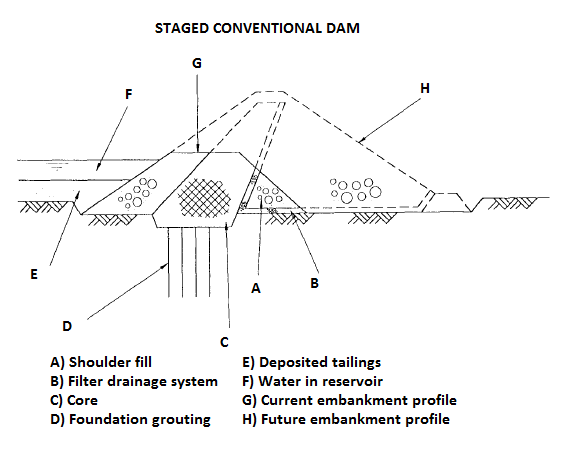

A staged conventional dam is similar to the conventional dam but is constructed in several stages. A benefit of this dam type is that the capital costs are spread over the operation phase. The starter dam core and the new stage core and draining structures must be accurately constructed so that the structure is continuously coherent (Figure 3) (ICOLD 1996b, European Commission 2009).

Figure 3. A staged conventional dam (modified after ICOLD 1996c, European Commission 2009).

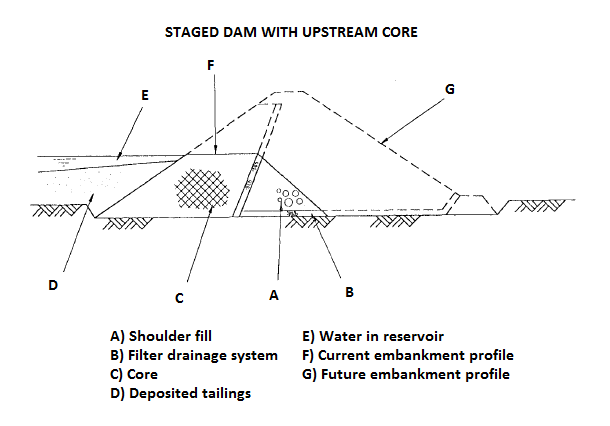

A staged dam with an upstream core is suitable to be used in impoundments, where the tailings deposit lies close to or above the free water level. The impermeable/low permeability core is located on the upstream face and there is no need for an upstream shoulder structure, because the tailings deposit protects the dam core against erosion. (Figure 4) (ICOLD 1996c, European Commission 2009).

Figure 4. A staged dam with an upstream core (modified after ICOLD 1996c, European Commission 2009).

Permeable dams

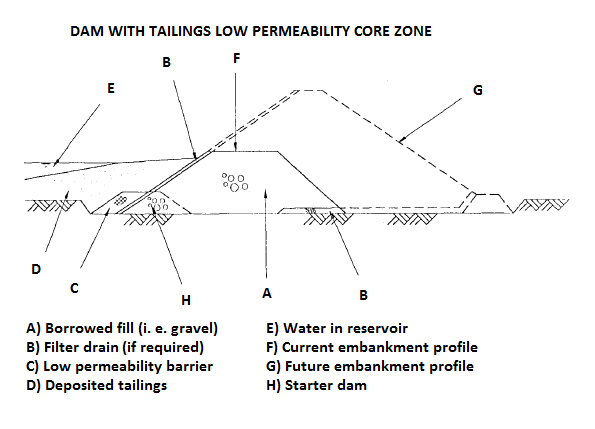

Tailings dam with low permeability core zone: The starter dam is impermeable and the staged dam above it is made of more permeable soil material such as borrowed fill (e.g. gravel). The deposition of the tailings into the pond arises above the water level forming a beach against the dam. This beach provides less permeable cone and protects the actual dam structure from erosion; it acts as water barrier. Water level monitoring is required, because it is not allowed to rise above the beach level. There is also a risk of pollution via seepage water and thus a filter may be needed (Figure 5) (ICOLD 1996c, European Commission 2009).

Figure 5. A tailings dam with low permeability core zone (modified after ICOLD 1996c, European Commission 2009).

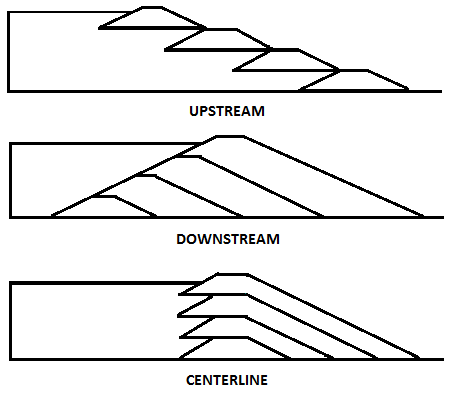

Dams with tailings in structural zone is similar to previous dam type, but tailings have been used as a construction material, which is a cost-effective solution. A hydrocyclone is typically used to separate finer and coarser tailings fractions: the finer fraction is discharged to the pond and beach and the coarser fraction forms the actual dam structure. A staged dam can be constructed on the starter dam in several ways (Figure 6) (ICOLD 1996c, European Commission 2009):

- Downstream construction: Coarser tailings separated by the hydrocyclone are discharged to downstream of the starter dam crest (underflow). The starter dam expands and forms a new toe for the dam requiring a lot of material and surrounding space. A finer fraction (overflow) is conveyed into the pond. The main problems concern the poor stability and susceptibility to liquefaction. Especially the finer fraction is less dense and unable to drain or consolidate, so the pore pressure may be high (ICOLD 1996c, European Commission 2009).

- Centreline construction: This construction method mixes upstream and downstream methods. The downstream embankment is made of coarse tailings material and the upstream face of the dam is supported by the deposited tailings. The starter dam and staged raisings are in a vertical line. This method requires less material than downstream construction method, which may need to be supplemented by borrowed fill material (ICOLD 1996c, European Commission 2009).

- Upstream construction: This method is economical because only a narrow top zone is needed at one stage. Disadvantages are the settlement and stability problems when the beach layers below the top zone begin to consolidate. This method is not suitable for acid rock drainage material. Also the phreatic surface and liquefaction must be monitored (ICOLD 1996c, European Commission 2009).

Downstream and upstream methods can be also combined. For example, the first and second raising stages after the starter dam may be constructed using the downstream method with blasted rock, and the latter stages may be constructed according to the upstream method with tailings. This leads to the bottom part of the dam being more stable, but the material savings are larger in the latter stage (ICOLD 1996c, European Commission 2009, Kauppila et al. 2013).

Figure 6. Dams with tailings in structural zones. An example of an upstream, downstream and centreline construction (European Commission 2009).

Upstream construction using a beach or paddock is a traditional method to form a dam without the use of special grain size separators such as hydrocyclones; the beach acts as a separator itself. The tailings from a beach upper end near the crest are shovelled by hand, using light machines, or discharge of tailings is controlled in other way to raise the downstream edge. The downstream slope needs to be controlled (ICOLD 1996c, European Commission 2009).

Other dams at the mine site, such as underground supporting dams for empty mine pits are constructed for example by using borrowed fill materials, waste, blasted rocks or concrete, depending on materials available and water permeability demands. Tailings may be also used, if it does not cause any harm to the groundwater (Heikkinen et al. 2008).

Appropriate applications

Dams offer a good way to manage great amounts of tailings and water. A properly functioning dam prevents also pollution and other negative impacts on the surrounding environment. On the other hand, there are many potential problems and hazards when tailings dams are used. Instability, overtopping, and internal erosion are potential risks. Dams are long-life structures, so the proper design, operation and regular monitoring are essential for their durability and affect also to the closure phase measurements and monitoring (European Commission 2009). Stability, ability to carry loads, slopes, erosion, pore pressure, acid generation etc. may change and develop during the whole mine operational life in case of dams that are constructed and raised step by step (European Commission 2009, Vanden Berghe et al. 2011). A good designer takes the mine closure phase into account already from the beginning of the design and construction phases of the dam.

Many aspects affect to the selection of the suitable dam type. These aspects are e.g. the purpose of the dam, a deposit material, available construction materials, soil structure / ground conditions at the site, available construction time, raising needs, loads, weather conditions and economic restrictions. (European Commission 2009, Kauppila et al. 2013) The dams also differ from one to another based on the water diversion inside the structure. Some dams are impermeable (conventional dams) or water may flow throughout the structure in a controlled way e.g. via channels, pipes or other drainage system. A general principle is that the conventional dam is the safest choice if the impoundment must act as water storage, tailings are not suitable for construction and/or the seismic risk is high (European Commission 2009).

Applications and suitability of the most typical dam types are listed in Table 1.

Table 1. A comparison of different dam types (ICOLD 1996b-c, European Commission 2009, Vanden Berghe et al. 2011, Kauppila et al. 2013).

| Dam type | Applicability | Material | Advantages | Disadvantages | Monitoring |

| Conventional dam |

|

|

|

|

|

| Downstream tailings dam construction |

|

|

|

|

|

| Centreline tailings dam construction |

|

|

|

|

|

| Upstream tailings dam construction |

|

|

|

|

|

Performance

Dams are long-life structures and their sustainability and risk issues must be taken into account. One of the most important aspects concerning dams during the mine closure phase is safety. The safety must be ensured by rehabilitation, control and monitoring. Safety contains both physical and chemical issues, and includes also effects to health, environment, infrastructure and economy etc. and they must be taken into account in the dam concept design as early stage as possible (Kauppila et al. 2013, ICOLD 2013). According to ICOLD (2013) a goal of the closure plan of the tailings dam is to leave the structure in a condition, which “permanently withstand natural forces and not cause ongoing harm to the environment”. The dam structure and the deposit site are made as self-sustaining, so that ongoing maintenance is not needed. (Kauppila et al. 2013, ICOLD 2013)

A closure plan covers the pollution prevention, minimization of impacts, long term stability and a site-specific approach for each facility on aesthetics and land planning (ICOLD 2013). A post-closure maintenance is done regularly right after the mine closure phase, but the monitoring can be done less frequently when the structure is stabilized and the possible emissions are decreased to a sufficient level.

Maintenance and monitoring costs have to be covered by financial guarantees. The financial plan includes e.g. the following components (ICOLD 2013):

- Estimation of the closure costs

- Monitoring and management costs

- Costs of progressively done treatments

- Allowance for risk contingency. (ICOLD 2013)

The closure plan is made according to regional requirements and regulations; In Finland these guidelines are addressed in Dam Safety Act 26.6.2009/494 and Mining Act 621/2011 and e.g. in the Dam safety guide (Isomäki et al. 2012). A risk assessment may be good tool to evaluate risks and their influences (ICOLD 2013). It should be bear in mind that the mine personnel is often not experienced with the dams, so proper education and understanding concerning the dam design, rehabilitation and regular monitoring are important (Martin & Davies 2000).

The designed service life of the dams varies, but according to ICOLD (2013) the expected length of life may be even 1,000 years or more. A general guideline for the best available technique is to design a lower hazard dam for capacity of 100 year flood and a high hazard dam for 5,000-10,000 year flood (European Commission 2009).

Design requirements

Design requirements for dams vary remarkably and many planning guides and publications exist, for example the whole ICOLD series (ICOLD 1996a-c, 2013; European Commission 2009, Isomäki et al. 2012). Some requirements suitable for Finnish conditions are presented in Best Environmental Practices in Metal Ore Mining (Kauppila et al. 2013). In Finland dams are divided into three sectors based on the safety risks and hazards to the environment. This classification is presented in Table 2. In Table 3 a part of the design requirements is presented, also taking the dam classification into account.

Table 2. The Finnish Dam Classification (Isomäki et al. 2012).

| Class | Description |

| 1 | Dam, which the event of an accident causes danger to human life and health or considerable danger to the environment or property. |

| 2 | Dam, which the event of an accident may cause danger to health or greater than a minor danger to the environment or property. |

| 3 | Dam, which the event of an accident may cause only a minor danger. |

| Unclassified | Classification does not need to be made if the dam safety authority considers that the dam does not cause any danger. |

| Characteristics | Requirements |

| Stability | Settlement and stability dimensioning must be done in such a way that no landslides will occur.

The phi factor (overall working coefficient) of the earth dam in permanent seepage flow situations is at least 1.3. The phi factor during the construction stage or in cases of sudden drops in water level is at least 1.3. |

| Dam filtering structures and drainage | The filter/drainage system must be capable to handle 10 x the theoretical seepage quantity. Filters/drainage system must not retain water.

The permeability of the filter must be 10-100 x of the protected material. The compacted dam core is extended down to the impermeable subsoil/bedrock (which is injected if necessary). |

| Freeboard/beach | Freeboards are defined according to:

wave height; 1.75 times the greatest wave height or frost depth; most relevant for mine dams. For class 1 and 2 dams the 10 years maximum frost depth (F10) is used, for class 3 dams the 5 years maximum (F5) is used. |

| Dam safety margin (difference between the top of the sealing section to the HW level) | For class 1 and 2 dams at least 0.4 m, and for class 3 dams at least 0.3 m. Settlement margins must be included into these numbers. |

| Crest of the dam | The crest width for class 1 and 2 dams is at least 4 m.

If the height exceeds 10 m, a width of 0.5 m is added for the start of each 10 m high increment. Class 2 dams less than 4 m in height, a crest width of 3.5 m is allowed. For class 3 dams the crest width is at least 3 m. |

Dam construction and raising materials must be geotechnically and environmentally suitable (Kauppila et al. 2013). They must not weaken under operational or climatic conditions (European Commission 2009). Used materials may be tailings, borrowed soils as sand, gravel or till, waste rocks and blasted rocks. Also concrete and other traditional construction materials can be used e.g. in the supporting dams. Especially the tailings slurries are often weak and loose, but they are economical and easily available (Kauppila et al. 2013). Often the tailings must be processed before using them in the construction. These processes typically include a grain size separation by for example a cyclone, spigotting or spraybar; drainage to lower phreatic surface and therefore better stability and strength; and mixing with coarser materials (European Commission 2009, ICOLD 2013). Waste and blasted rocks are often stabile and good for construction, but the availability and costs restricts their use. The same problem pertains to borrowed soils. Many dams include an impermeable core, which can be made of borrowed clay or artificial materials.

The target of rehabilitation at the closure phase is to construct the dams as stable as possible having a safety factor at least 1.3 (European Commission 2009). The rehabilitation procedure varies depending on whether the deposit will be dewatered or under water (ICOLD 2013).

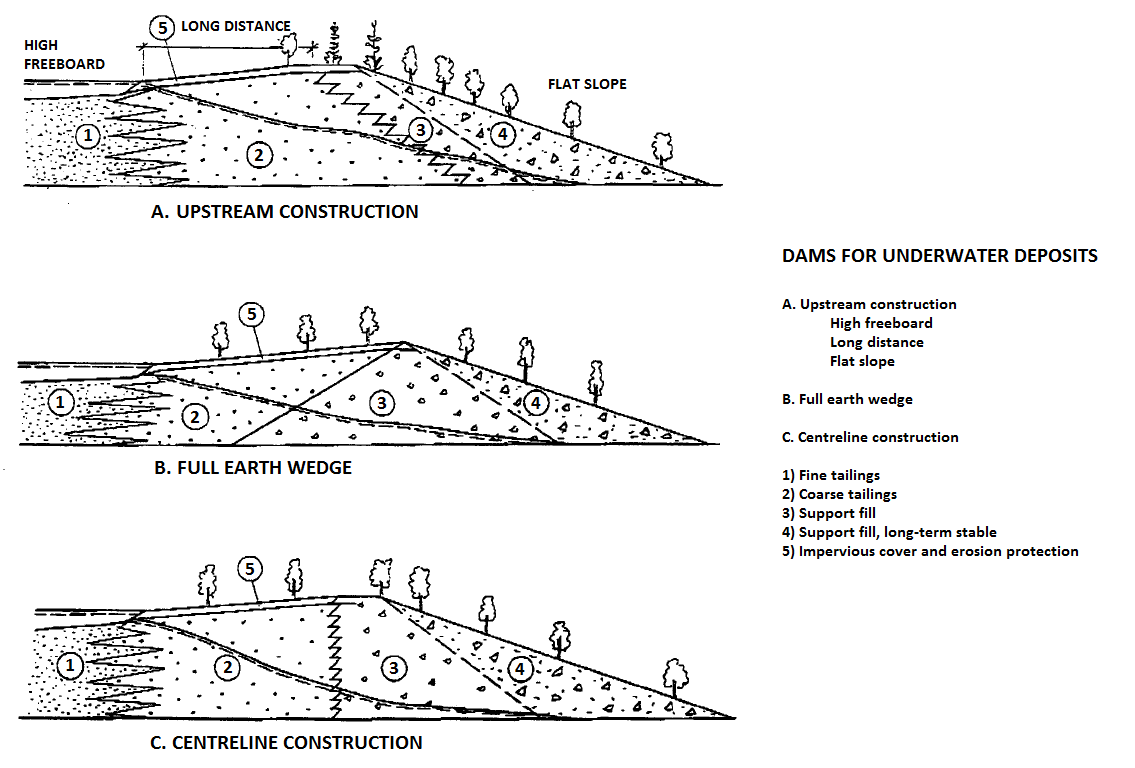

The underwater deposit is suitable for tailings or other material, which need an effective long-term seal against oxygen and weathering, such as acid forming tailings (see: water covers). The embankment stability must be assured; the possibility for slope failure must be low (e.g. 1:3 (ICOLD 2013)), dam should be designed for extreme flood events, earthquakes and high wave actions. The construction material of the dam must resist weathering and weakening caused by internal/outer erosion. The pore pressure should be low; therefore the phreatic surface must be controlled. When the beach is sufficiently wide, the phreatic surface does not rise too close to the dam crest and the dam remains more stable. Some examples concerning the water covered deposits and dam arrangements are presented in Figure 7. (European Commission 2009, ICOLD 2013)

Figure 7. Dams for underwater deposits (modified after ICOLD 1996b).

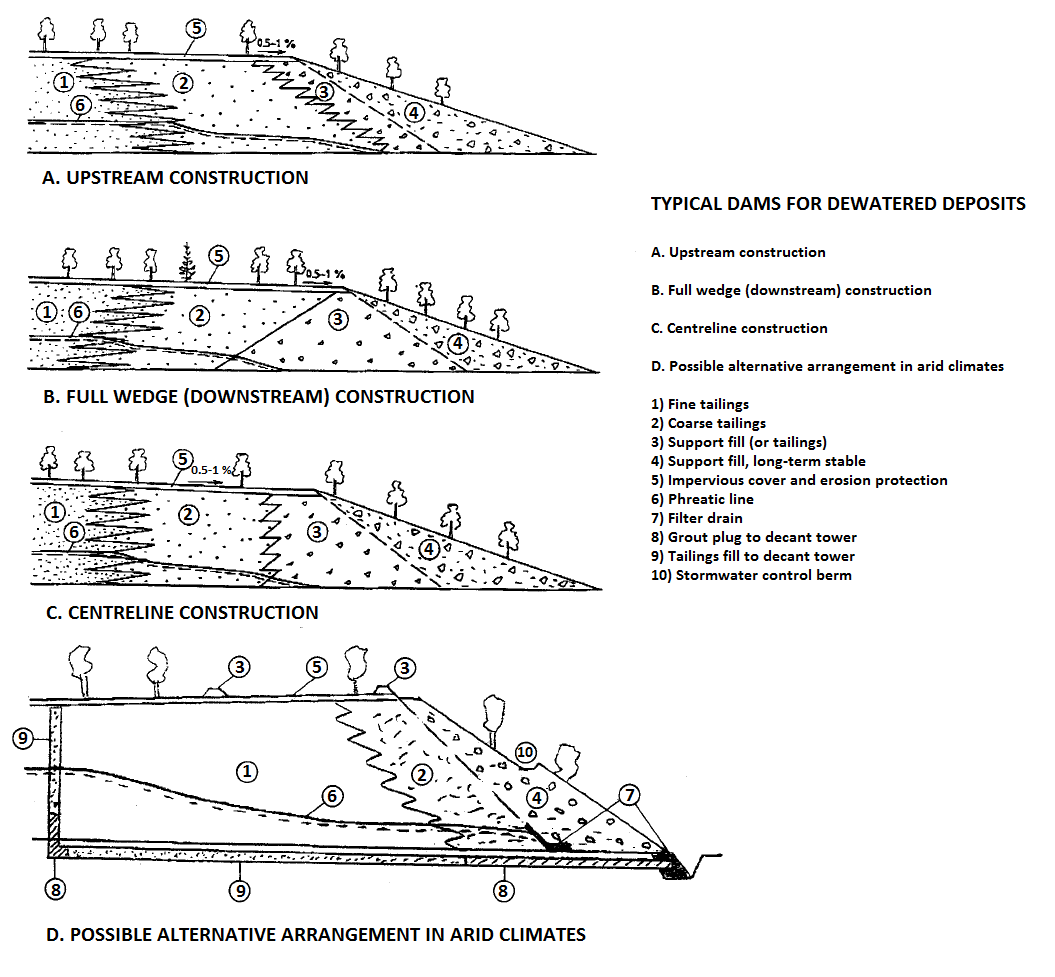

The long-term stability of a dewatered deposit is easier to achieve than in the case of an underwater structure. The phreatic water level is lower which increases slope stability and internal erosion. However, the slopes may still need forming and seepage through an embankment needs controlling. Also the beach should be sufficient to prevent overtopping. The deposited material should be resistant against weakening caused by erosion and weathering; the acid forming materials should be covered to inhibit infiltration and diffusion. The dewatered structure needs a drainage system as decant towers and spillways, which are not tend to clogging or damaging during long-term phase. (ICOLD 2013) Some examples of dewatered deposit and dam systems are presented in Figure 8.

Figure 8. Dams for dewatered deposits (modified after ICOLD 1996b).

Rehabilitation in the post closure phase of other dam types includes similar actions than in the case of tailings dams. The forming or gradation of steep slopes and ramps increases stability of the dams and heaps. Other feasible methods to improve stability include the construction of supporting banks on the downstream toe of the dam and lowering the seepage water by pumping. Underground dams (and backfilling) may be needed in areas, where roads and other structures lie above the underground mine and the tunnels and excavations need support or confining structures. Landscaping and vegetation are also often an important part of closure action for dams. Sometimes the demolitions of unnecessary dam structures are made, e.g. in case of decant impoundments (Heikkinen et al. 2008, Kauppila et al. 2013).

The post closure phase is divided into active and passive care periods. During the active care period an active monitoring and possible interventions are required to achieve a final stable form. When dam is brought to the passive care phase the dam is monitored to ensure its compliance with the closure objectives. This period is necessary until the dam is considered to be physically, chemically, economically and socially stable and safe to life and environment; reaching this stable stage may take a long time (European Commission 2009).

Monitoring is presented in the section ”Monitoring”. Generally, the dam monitoring should include inspections concerning stability, ground movements, erosion and water conditions, such as pore pressure and phreatic surface, and recording of any changes (ICOLD 1996a, Martin & Davies 2000, European Commission 2009). Often the importance of these measurements is underestimated; the monitoring frequency should be regular, surveillance program followed, and staff educated. The monitoring of tailings dam differs also from the monitoring of conventional dams (Martin & Davies 2000). The surveillance program has to be planned to take into account of the specific site conditions (ICOLD 2013). The long-time target is to reduce the monitoring frequency (depends on the development of the dam stabilization).

References

European Commission (EC) 2009. Reference document on Best Available Techniques for Management of Tailings and Waste-Rock in Mining Activities. January 2009, European Commission. 511 p. http://eippcb.jrc.ec.europa.eu/reference/BREF/mmr_adopted_0109.pdf

Heikkinen, P.M. (ed.), Noras, P. (ed.), Salminen, R. (ed.), Mroueh, U.-M., Vahanne, P., Wahlström, M., Kaartinen, T., Juvankoski, M., Vestola, E., Mäkelä, E., Leino, T., Kosonen, M., Hatakka, T., Jarva, J., Kauppila, T., Leveinen, J., Lintinen, P., Suomela, P., Pöyry, H., Vallius, P., Nevalainen, J., Tolla, P. & Komppa, V. 2008. Mine closure handbook. Outokumpu Oyj, Finnish Road Enterprise, Soil and Water Ltd., Geological Survey of Finland (GTK) and Technical Research Center of Finland (VTT), Espoo. 169 p. http://arkisto.gtk.fi/ej/ej74.pdf

International Commission on Large Dams (ICOLD) 1996a. Monitoring of Tailing Dams. ICOLD Bulletin Preprint 104.

International Commission on Large Dams (ICOLD) 1996b. Tailing dams and environment. ICOLD Bulletin Preprint 103.

International Commission on Large Dams (ICOLD) 1996c. A guide to tailings dams and impoundments – design, construction, use and rehabilitation. ICOLD Bulletin Preprint 106.

International Commission on Large Dams (ICOLD) 2013. Sustainable design and post-closure performance of tailings dams. ICOLD Bulletin Preprint 15

Isomäki, E., Maijala, T., Sulkakoski, M. & Torkkel, M. (eds.) 2012. Dam Safety Guide. Häme Centre for Economic Development, Transport and the Environment, Reports 89/2012. 90 p.

Kauppila, P., Räisänen, M. L. & Myllyoja, S. 2011. Best Environmental Practices in Metal Ore Mining. Finnish Environment 29 en/2011. 219 p.

Martin T. E. & Davies, M. P 2000. Development and review of surveillance programs for tailing dams. AGRA Earth & Environmental Limited, Burnaby, BC. 16 p.

Vanden Berghe, J.-F., Callard, J.-C., Wintgens, J.-F. & List, B. 2011. Geotechnical risks related to tailing dam operations. Proceedings Tailings and Mine Waste 2011, Vancouver, BC, November 6 to 9, 2011. 11 p.

Leave A Comment

You must be logged in to post a comment.