Britannia Mine, British Columbia Canada - Water management techniques and active water treatment after closure

Clayton Larkins, Geological Survey of Finland GTK, P.O.Box 1237, FI-70211, Kuopio, FINLAND, email: clayton.larkins(at)gtk.fi

Introduction

The Britannia Mine is located adjacent to the Howe Sound of western British Columbia, approximately 45 km north of Vancouver. The mine operated from 1905 to 1974 and produced approximately 48 million tons of primarily copper and zinc ore (O’Hara 2007). The regional geology is composed of volcanic and sedimentary rocks of the Lower Cretaceous Gambier Group, and plutonic diorite to granodiorite of the Coast Plutonic Complex. Ore bodies included sulphides, altered host rock and mineralized veins within the Britannia Shear Zone, a zone of shear deformation and metamorphism that dips steeply south and strikes to the northwest across a plutonic roof pendant (Price et al. 1995).

Mining operations were spread across an area of approximately 4,000 hectares, and include 80 km of underground workings with numerous portals, glory holes, four open pits, and mineral processing facilities (O’Hara 2007). The open pits and numerous glory holes are located in the Jane Creek Basin (Jane Basin), where the primary ore body outcropped. Jane Creek feeds Britannia Creek from near the top of Britannia Ridge. Britannia Creek drains to the Howe Sound, several kilometres to the west (Figure 1). Major mine portals located along Britannia Ridge include the 2200, 2700, and 4100 level adits. Additional glory holes and major portals, including the Victoria and Beta Camp portals, are in the Furry Creek watershed to the south of Jane Basin (O’Hara 2007). The 4100 level adit was the mine’s deepest major portal, and is located just east of the former mineral processing area (O’Hara 2007).

Figure 1. Aerial image of Britannia Mine site including inset of southern Britannia Beach, alluvial fan area. The location of all labeled features are approximate. (adapted from Golder 2003, 2011, basemap copyright © ESRI 2015)

Mineral processing throughout mining operations was conducted at the south end of Britannia beach, on the Britannia Creek alluvial fan (the Fan Area). Three separate mills operated at the Britannia Mine, all within this same general area (URS 2002a). Ore was ground to fine sand and extracted by flotation. Ore concentrate was dewatered and exported by ship for smelting off-site (URS 2002a). Copper launder systems used to precipitate copper for recovery from mine water discharge were installed near several adits, the largest of which was at the 4100 level adit (URS 2002a).

The Britannia Mine site is a major source of metals laden acid rock drainage (ARD) that impacts Britannia Creek, Furry Creek and the Howe Sound. The primary contaminants of concern are elevated levels of copper, zinc and to a lesser extent lead and cadmium in mine impacted effluent (Golder 2003). Contamination migrates in surface and groundwater that is impacted from various site-wide contaminant sources. The site’s largest contaminant source is water discharged from the underground mine workings (Golder 2003). Prior to remediation efforts, approximately 5 million m3 of water with an average pH of 3.5 discharged from the mine workings to Howe Sound annually (O’Hara 2007). Additional contaminant sources include deposits of tailings, waste rock, precipitate sludge, ore concentrate and exposed mineralized rock throughout the site (Golder 2003). These contaminant sources will be collectively referred to as waste deposits.

A multi-phase, iterative, risk based approach to remediation commenced in 2001 (Golder 2003). Remedial actions have included the design and installation of a groundwater management system (GMS) and a water treatment plant (WTP). Additional measures have included waste deposit removal from sensitive areas, drainage enhancements and surface water diversions (Golder 2011). Discharge from the mine workings has been reduced and impacted waters are treated prior to being discharged to Howe Sound from a deepwater outfall. Monitoring, however, has indicated that metals loading from storm water runoff and groundwater continues to impact the ecologically sensitive intertidal zone in the vicinity of the Fan Area. Subsequently, planning for the expansion and optimization of remedial actions is on-going (Golder 2013).

Mine closure objectives

The objectives of mine closure were defined in the Overall Mine Closure and Site Remediation Plan (OCP) and are summarized below (Golder 2003).

- Reduce contaminant discharge to facilitate the natural recovery of the aquatic environment to an acceptable regulatory state through the collection and treatment of ARD, and the removal and isolation of ARD generating materials

- Protect and promote the recovery of aquatic communities through continued monitoring and adaptive remedial actions

- Maintain the health and safety of humans and terrestrial life within acceptable risk levels in accordance with mine closure safety requirements

- Conduct remediation in a cost and time efficient manner while still ensuring long term effectiveness. Prioritize remedial actions based on the greatest ecological benefit using an iterative process of action, monitoring and assessment

After mine closure, water discharged from mine workings was determined to account for approximately 95% of the site’s metals loading to Howe Sound (O’Hara 2007). An estimated 85% of the water discharged from the mine workings was attributed to infiltration of meteoric waters (SRK 2003a). Infiltration occurs through glory holes, open pits and fractured bedrock overlying the mine workings. Primary discharge points were identified as the 2200 and 4100 level adits (O’Hara 2007). Discharge from the 4100 level was routed to an outfall in the sound 26 meters below sea level. Discharged mine water had high concentrations of numerous metals and metalloids of potential concern, including antimony, arsenic, barium, cadmium, chromium, copper, lead, molybdenum, nickel, selenium, silver, tin, and zinc (Golder 2003). The largest contaminant loadings were from copper and zinc, which were each estimated to be approximately 300 kg per day to Howe Sound (O’Hara 2007).

Metals leached from site-wide waste deposits were also determined to contribute significant loading to the sound (Golder 2003). One of the largest concentrations of acid generating waste is in the vicinity of historic ore processing on the Fan Area. Contaminated groundwater and storm water runoff from the Fan Area discharges directly to Howe Sound’s environmentally sensitive intertidal zone. The other major waste deposit area is the open pit and glory hole complex of Jane Basin. Contaminant sources at mine portals, town sites, and camp areas also discharge to both the Britannia and Furry Creek drainages (Golder 2003). The approximate copper and zinc loadings discharged to Howe Sound from these sources prior to remediation are shown in Table 1.

Table 1. Pre-remediation sources of dissolved metal loading to Howe Sound (adapted from O’Hara 2007)

| Source area |

Cu (kg/day) |

Zn (kg/day) |

Cu% |

Zn% |

|---|---|---|---|---|

| Alluvial Fan |

10 |

16 |

3.26 |

5.19 |

| Britannia Creek |

3 |

4 |

0.98 |

1.30 |

| Furry Creek |

1 |

1 |

0.33 |

0.32 |

| 4100 Level* |

293 |

287 |

95.44 |

98.18 |

| Total |

307 |

308 |

100 |

100 |

*This table represents 4100 level loadings after the 2200 level discharge was rerouted to the 4100 level. Therefore, 4100 level loadings are based on total mine workings discharge.

Britannia Mine emissions impact terrestrial, freshwater, and aquatic ecology in the mine site vicinity (URS 2002a, 2002b, 2003, Hagen et al. 2004). Based on risk assessment studies, mine site emissions did not pose unacceptable levels of risk to human health (URS 2002b, 2003). Minor impacts were observed in terrestrial vegetation and no invertebrates were observed in the soils of the Fan Area (URS 2002a). Elevated concentrations of copper, zinc, and to a lesser extent lead and cadmium in soils across the site were determined to pose risk to terrestrial biota, including the red alder, American robin, deer mouse, black tail deer, and screech owl (URS 2003). Life in creeks draining the mine site and in the intertidal zone was sparse (Hagen et al. 2004, URS 2003). No fish and few macroinvertebrates were observed in the fresh water drainages (URS 2003). Key local species such as mussels, rock weed and shore crabs were absent from the intertidal zone of of the Fan Area and for several hundred meters to the north along Britannia Beach. While the predominant flow direction along Britannia Beach is to the north, these species, as well as barnacles, were more abundant to the south of the Fan Area, with increasing abundance at greater distance from the Fan Area (Hagen et al. 2004, URS 2003). The apparent impacts to intertidal populations were attributed to elevated metals concentrations in surface water, sediments and soils in the Fan Area (URS 2003).

Description of closure technologies, methods, and concepts

Concepts

The remediation design utilizes a risk based, iterative approach to prioritize remedial actions that provide the largest risk reduction per cost (Golder 2003). Remediation progressed in three phases defined by specific remediation, monitoring, and assessment actions. The remedial action of each progressive phase was based on monitoring and assessment results. The design phases and specific actions, as described by the OCP, are summarized below (Golder 2003):

- actions that had been taken or were immediately underway at the time of the OCP

- rerouting mine water discharge from the 2200 level to the 4100 level

- stabilization and remediation of point source contaminant material such as highly contaminated soils in the processing area

- capture and rerouting Fan Area groundwater discharge

- drainage enhancements to control storm water

- implementation of environmental monitoring and risk assessment

- actions that were to be conducted upon sufficient data collection

- design and construction of a WTP for mine water discharge (completed 2005)

- design and construct new deepwater fallout for captured and treated waters (completed 2005)

- construct surface water controls (on-going)

- refined monitoring and second tier risk assessment (2004 to 2007)

- possible actions to be taken based upon ongoing monitoring and risk assessment

- expand GMS (two additional pumping wells have been added)

- additional storm water drainage controls (design development on-going)

- additional surface water diversions (site study on-going)

- additional remediation of sub-aerial and intertidal mine waste on site (site study on-going)

Methods and Technologies

Groundwater Management

A single pumping well was installed in the Fan Area in 2003 to temporarily mitigate discharge of contaminated groundwater to Howe Sound and to provide design data for a GMS. The pumping well discharged to the deepwater outfall. Upon completion, the GMS also routed captured water to the deepwater outfall until the WTP began operation, at which point captured groundwater was routed for treatment (Golder 2004a).

A design challenge during development of the GMS was to limit the capture of saline marine water which was anticipated to intrude the Fan Area as groundwater plumes were pumped down. Captured saline water would cause corrosion to components of both the GMS and WTP. Additionally, captured marine water would induce uncertainty in water quality, specifically chloride concentrations, and water volumes being routed for treatment (Golder 2004a). Subsequently, the GMS was designed to accommodate the following WTP operational requirements: a maximum combined pumping rate of 100 m3 per hour, with chloride concentration maintained below 1000 mg/L (Golder 2004a). Numerical groundwater modelling was conducted to optimize the placement of pumping wells for the most effective capture of contaminated groundwater, while minimizing marine water intrusion and capture. Seven pumping wells with corrosion resistant components were installed along the southern Fan Area. As part of the optimization process pumping rates were initially controlled manually, and eventually automated to control flow rate and water quality (Golder 2005). As part of the iterative remedial process, two additional extraction wells were added to the GMS to increase the efficiency of groundwater capture to approximately 90% (O’Hara 2007).

Soils remediation

As of 2010 approximately 50,000 m3 of contaminated waste material had been relocated to the Jane Basin (Golder 2011). A total of 123,500 m3 of contaminated material has been planned for disposal in the basin (Golder 2006). These materials have been determined to have similar acid production properties as the exposed materials in the open pit and glory hole complex, and are not expected to significantly contribute to the contaminated discharge from the basin. Water leached from the waste materials in Jane Basin enters the mine workings and is treated at the WTP upon discharge (Golder 2004b).

Surface water management

Site surface water management has included drainage system development and stream diversions. As part of phase 1 remedial actions a storm water collection system for the Fan Area was constructed. The system utilizes lined surfaces, swails, catch pits and pipe systems to capture and route storm water runoff from the highly contaminated historic processing areas to be discharged to the deepwater outfall. Phase 1 hydrologic investigations led to the construction of three surface water diversions during phase 2 operations, from 2004 to 2005. These diversions prevent fresh water from infiltrating mine workings in the Jane Basin and Victoria Mine areas, therefore reducing total mine water discharge (O’Hara 2007). The Upper Jane Creek and East Bluff diversions direct water away from Jane Basin and discharge to Britannia Creek. The Victoria Mine diversion directs water away from the Victoria glory hole to Furry Creek (O’Hara 2007). The combined influence of these three diversion structures was predicted to reduce annual mine water discharge by approximately 23% (SRK 2003c). Ongoing drainage enhancements have included a surface water diversion away from the 4100 level copper laundering area and into the Britannia Creek in 2009, and a diversion away from the Mine Tour Entrance in 2010 (Golder 2011). Study of site hydrology for the design of drainage improvements is an ongoing component of the iterative remediation process at the site (Golder 2013).

Water treatment

Initial remedial action was taken in 2001 by plugging the 2200 level adit in order to route the mine workings discharge to a single discharge point at the 4100 level adit. Consolidating mine water discharge facilitated the planning and design of water treatment options (SRK 2002, O’Hara 2007). Detailed geochemical and hydrogeological studies, including plug testing to evaluate the use of mine workings as a reservoir, were conducted to inform WTP design criteria (SRK 2002, 2003a, 2003b).

To further isolate the sound’s intertidal zone from mine site impacts, the deepwater outfall was relocated to discharge from a diffuser 50 m below sea level (Golder 2003, O’Hara 2007).

A high density sludge (HDS) WTP was determined to be the preferred water treatment technology at the Britannia Mine site (Golder 2003). Optimizing the size and capacity of the WTP was a design challenge due to the high seasonal variability in mine water discharge, which ranges from approximately 40 to 400 L per minute (O’Hara 2007). Mine workings between the 4100 and the 3250 levels were utilized as a mine water reservoir to manage mine water discharge rates across the seasons, subsequently allowing for a more efficient WTP design capacity. A WTP with 1050 m3 per hour capacity was determined to provide the most effective and cost efficient water treatment option (Golder 2003). Plant construction was completed, and operation began in 2005. The plant treats mine water discharged from the 4100 level and the groundwater captured from the Fan Area. Influent flow rate to the plant is controlled by a valve in the 4100 level plug, and by the automated GMS. Additionally, two hydroelectric turbines were installed at the 4100 level discharge point, which produce approximately half of the WTP’s electrical needs (O’Hara & Azevedo 2008). When influent surpasses plant capacity, the plant design allows partial bypass of influent. Lime treatment of bypass water, and dilution with treated water prior to discharge to the deepwater outfall enables up to approximately 1,400 m3 per hour to be discharged within permitted dissolved metals criteria. Total dissolved solids may exceed permit criteria during capacity exceedance events (Golder 2003).

Interdependence

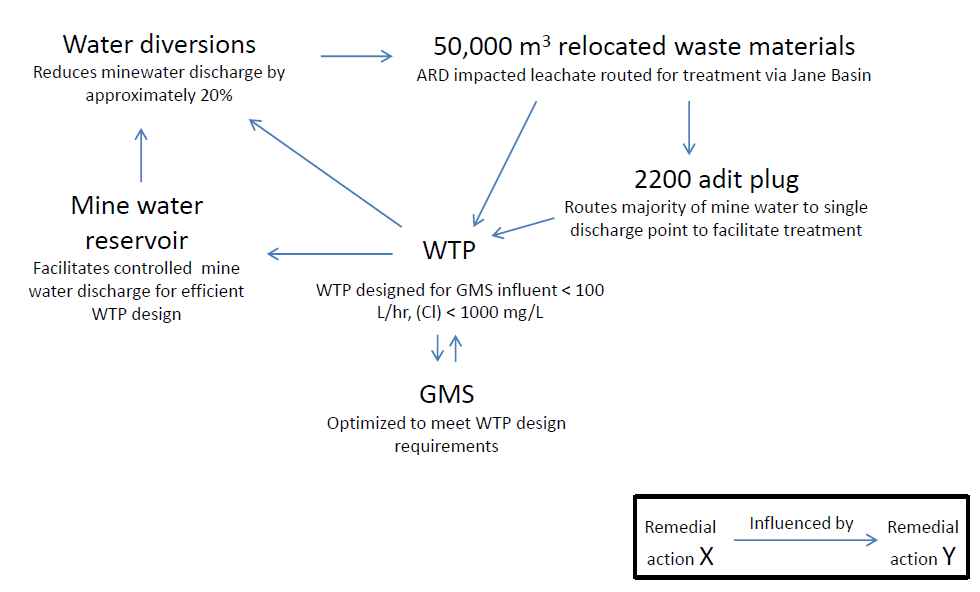

The remediation approach at the Britannia site includes various remediation measures to limit the migration of contaminated water and to treat ARD emissions. Individual remediation methods are employed as interdependent components of the OCP to reduce emissions. For example, the design and effectiveness of the WTP is dependent on influent water quality and quantity from sources such as the GMS and mine workings reservoir. Conversely, influent sources are designed to accommodate the most practical WTP design options.

Various remediation actions that have been taken to limit the migration of contaminated waters include implementation of pumping wells as part of the GMS, surface water and storm water drainage enhancements, surface water diversions, plugging mine water discharge points, and development of a mine water reservoir. These measures are interdependent with water treatment, and largely with one another for the management of site ARD emissions. Figure 2 summarizes the interdependence of the major water management methods.

Figure 2. Britannia Mine site water management methods and interdependence

Alternative methods

Various remediation alternatives have been considered for the site’s primary ARD sources (SRK 1991). While remedial alternatives for contaminant sources across the site have been investigated historically (e.g. SRK 1991, Vos & O’Hearn 1993), final remedial decisions were defined through the detailed site studies and risk assessments of the Britannia Mine Remediation Project that commenced in 2001 (O’Hara 2007).

As identified through a 1991 site evaluation of remedial alternatives, large amounts of oxidation products existed at various ARD source points throughout the site, including within the open pits and glory holes, within mine workings, and within soils and sediments contaminated by mine and processing waste (SRK 1991). The contamination of meteoric water results from water captured in mine workings and the infiltration of storm water and stream water into waste deposit material (SRK 2003a). Therefore a primary focus of preventative water management has been to reduce contact between clean meteoric water and contamination sources (O’Hara 2007, Golder 2003).

The waste rock and exposed surfaces of the open pits and glory holes in Jane Basin impact the water that infiltrates into the underground mine workings. A remediation alternative considered for reducing the impact from these sources was the placement of geosynthetic liners over exposed reactive surfaces coupled with drainage diversions to prevent infiltration from precipitation and storm water flows (SRK 1991). These measures however, were determined impractical due to the difficult terrain, unstable surfaces and potential for subsidence that would likely result in cover failure (SRK 1991).

Covers and drainage diversions were also considered as a remedial option for waste deposits in the Fan Area. Waste deposit isolation using covers has potential advantages over waste removal, as there is less potential for contaminant mobilization, which is a concern during waste removal activities. Additionally, in-situ isolation measures prevent the need for off-site disposal, which requires identifying an appropriate disposal site (SRK 1991).

Stream water diversions were identified as a means to reduce surface water capture into the underground mine workings (SRK 1991). However, the size and complexity of the infiltration area, including scree slopes, glory holes and fractured bedrock, limits the possibility of surface water diversion as a sole solution for mine water discharge (Golder 2003). To address the emissions from mine workings discharge that could not be prevented by water diversion, water treatment was determined necessary (Golder 2003).

Numerous mine water treatment technologies were considered as part of a water treatment plant feasibility study (AMEC 2002). Water treatment technologies including biological sulphide, silica microencapsulation, electrorecovery, onyhydroxide treatment, Low Density Sludge, High Density Sludge, and electrocoagulation were evaluated based on performance, site-specific conditions, and operating costs to define the preferred technology for the Britannia site (Golder 2003). Ultimately, the HDS WTP was determined most suitable to the site-conditions.

Additional remediation options were proposed as part of the OCP, and may still be implemented based on ongoing monitoring and risk assessment results (Golder 2003). These actions include further removal of waste deposit materials such as waste rock, ore concentrate and metal precipitates from mine portals, stream beds, storage areas and processing areas (Golder 2003). Additional drainage controls, including capping of waste deposit areas, may be implemented to reduce contaminant migration in surface waters. Groundwater management controls could be expanded to include use of low permeability barrier walls or reactive barrier walls (Golder 2003).

Performance

Capacity

The WTP capacity was a primary consideration for plant design. A mine plug test was conducted and a mine reservoir model was developed to project influent water volume and quality to the WTP. Based on mine reservoir modelling and assessment of historic precipitation data, a WTP capacity of 1,050 m3 per hour was determined to provide the best balance between efficiency and effectiveness based on risk reduction. Modelling results projected an average flow of 585 m3 per hour, but due to seasonal and long term variability in precipitation, even a significantly larger plant with a capacity of 3,000 m3 per hour, would not be sufficient to treat 100% of mine water discharge (Golder 2003). The 1,050 m3 per hour WTP was predicted to treat 93% to 97% of annual mine water discharge. Discharge rates of up to 1,400 m3 per hour can be bypassed and lime treated to meet permitted dissolved metals requirements (Golder 2003). The minimum operational through-put is 25% of capacity. When mine discharge is below that rate, treatment is temporarily halted while the mine reservoir is filled until there is sufficient volume to again meet minimum discharge requirements (Golder 2003). A portion of the WTP influent is derived from the GMS, which is optimized to collect less than 100 L per hour and maintain chloride concentrations below 1,000 mg per L. When the WTP is not operating (e.g. when mine water discharge flow is too low) water from the GMS is bypassed to the deepwater outfall.

Capacity is also a consideration in the open pit complex of the Jane Basin that is used for the disposal of contaminated waste materials, and sludge form the WTP. The waste capacity of Jane Basin is estimated to be approximately 130,000 m3. Volumes under this capacity should not cause a significant impact to the quality of mine water discharged to the WTP (Golder 2006). As reported in 2010, over 50,000 m3 of waste has been deposited in the basin (Golder 2011). A total of 123,500 m3 of waste is planned for deposition in the basin (Golder 2006).

Maintenance needs

The need for ongoing maintenance of site facilities, including the WTP and GMS, was recognized during the remedial design process (Golder 2003, 2004a). Additional maintenance has been required on infrastructure providing access to monitoring and the waste disposal sites (Golder 2011).

Part of operational maintenance at the WTP is the handling and disposal of approximately 3,000 m3 of sludge generated annually (O’Hara 2007). The sludge is stock piled in a closed building on the plant grounds until it is transported for disposal in the Jane Basin (O’Hara & Azevedo 2008). Sludge is transported twice a year, in the late spring and fall, when Jane Basin is accessible by road (O’Hara & Azevedo 2008).

Inspection and maintenance is required on the components of the GMS. The groundwater management plan indicates the need for scheduled pump maintenance as the result of precipitate build-up and corrosion (Golder 2004a). Scale build up in the GMS forcemain has been reported to cause reduced flow, inhibiting certain GMS monitoring efforts, and has subsequently required maintenance attention (Golder 2013, EPCOR 2012).

Reliability and malfunction

The phased and iterative remedial approach undertaken at this site allows for adaptive site management in response to potential remedial design malfunctions. The implementation of this strategy is illustrated by the progressive development of the GMS. After the initial installation and optimizing phases of the GMS, extracted groundwater was found to have prohibitively high chloride concentrations, which required reduced capture efficiency to maintain water quality criteria for WTP influent (O’Hara 2007). Refined site data collected during the first phase of GMS operations enabled further calibration of the groundwater model, which led to the implementation of two additional pumping wells and increased GMS capture efficiency (O’Hara 2007, Golder 2011).

System designs also generally provide failsafe considerations in case of system malfunction. The GMS design allows for any one extraction well to be shut down for short term maintenance without significantly compromising the system’s performance (Golder 2004a). Groundwater from the GMS is discharged to the WTP from a forcemain. In the event that influent to the WTP must be bypassed, which may occur if the plant is shut down or plant capacity has been exceeded, bypassed water is lime treated prior to discharge from the deepwater outfall (Golder 2003, EPCO 2012). By discharging contaminated water to the deepwater outfall, even if water quality parameters are not achieved through treatment, the discharge has still been directed away from the ecologically sensitive intertidal zone of Howe Sound (Golder 2003).

Scale buildup in the GMS forcemain illustrates a malfunction induced by site-specific water quality conditions. While the need to resolve this issue and prevent future build-up is clearly recognized in a 3rd quarter 2013 project progress report, it was first identified in 2011, and has since caused restricted flow from the GMS to the WTP (Golder 2013).

A source for uncertainty in WTP operations is the use of mine workings as a water reservoir. While use of the mine workings to hold mine water facilitates manageable year long mine water discharge for treatment, the mine is considered a dynamic system, with the potential for structural failure (O’Hara 2007). Changes in the mine workings could reduce the effectiveness of their use as a reservoir, reduce control over mine water discharge rates, and potentially reduce WTP effectiveness. While EPCOR, the WTP contractor, manages the mine reservoir and reservoir discharge, the Province of British Columbia maintains responsibility for instances of failure outside the contractor’s control (O’Hara 2007).

Environmental cost aspects

Environmental costs are minimized through the use of environmental assessment and monitoring to drive site remedial decisions. Additionally, one measure toward operational sustainability is the utilization of a micro-hydroelectric turbine at the 4100 level mine water reservoir discharge point, which generates approximately ½ of the WTP’s electricity needs (O’Hara & Azevedo 2008).

Advantages and Disadvantage

Table 2 summarizes advantages and disadvantages of the water treatment of the Britannia mine site.

Table 2. Advantages and disadvantages of mine site remedial strategies

| Remedial Action | Advantages | Disadvantages |

|---|---|---|

| Groundwater Management System (GMS) |

|

|

| High Density Sludge Water Treatment Plant (HDS WTP) with 1,050 m3/hr capacity |

|

|

| Surface Water Diversions |

|

|

| Storm water and surface water drainage improvements |

|

|

| Point Source Contaminant Remediation |

|

|

Monitoring / control needs

In accordance with the OCP, site monitoring has evolved throughout remediation (Golder 2003). Initial monitoring included baseline biota and habitat surveys (URS 2002a, 2002b, 2003, Hagen et al. 2004). Beginning in 2004 environmental monitoring was conducted to evaluate the effectiveness of remedial actions and included monitoring of creek water, groundwater, intertidal water quality, and intertidal ecological parameters (Golder 2009). In 2008 monitoring was narrowed to focus on the tidal environment and subsequently includes intertidal surface water, bottom water, and pore-water chemistry, sub-tidal surface water and bottom water chemistry, and intertidal ecological parameters (Golder 2011).

Monitoring results indicate that elevated surface water and pore-water metals concentrations in sample reaches along Britannia Beach generally align with suppressed ecological diversity and lower population numbers in these reaches relative to reference sample areas (Golder 2009). Elevated metals concentrations in pore-water and surface waters in the vicinity of southern Britannia beach are attributed to contamination of storm water runoff and groundwater discharged to the sound from in-situ sources such as tailings and contaminated beach sediments (Golder 2011). These results have informed ongoing remediation efforts, including storm water collection system expansion and shoreline contaminant characterization (Golder 2013).

Conclusion

Risk based assessment and monitoring guides the ongoing remedial efforts at the Britannia Mine site. Water discharged from underground mine workings, groundwater, and surface water are the primary contaminant transport pathways at this site. Copper and zinc in ARD impacted waters are the primary contaminants of concern. Of potential receptors, the ecologically sensitive intertidal zone of Howe Sound is at the greatest risk from mine site effluent (URS 2002a, 2002b, 2003). As remediation progresses and site use changes, risk will be reassessed for the aquatic environment, terrestrial environment, and human health (Golder 2003). Remediation efforts are ongoing and are being expanded to address persistent elevated metals concentrations in the Britannia Beach intertidal zone. Ongoing design studies include additional surface water diversions, drainage and runoff management systems, and waste deposit remediation (Golder 2013).

References

AMEC 2002. Britannia Mine Water Treatment Plant Feasibility Study. Prepared for the BC Ministry of Water, Land and Air Protection. November, 2002. 61 p.

EPCOR 2012. Britannia Mine Water Treatment Plant Annual Report: 2011.

ESRI 2015. Image available at: http://www.arcgis.com/home/webmap/viewer.html?useExisting=1

Golder (Golder Associates) 2003. Overall Mine Closure and Site Remediation Plan: Britannia Mine, Britannia Beach, BC. Submitted to the BC Ministry of Sustainable Resource Management, Victoria, BC. October, 2003. 47 p.

Golder (Golder Associates) 2004a. Groundwater Management Plan South Fan Area: Britannia Mine, Britannia Beach, B.C. Submitted to the BC Ministry of Sustainable Resource Management and Ministry of Water, Land and Air Protection, August 6, 2004.

Golder (Golder Associates) 2004b. Report on Jane Basin Disposal Permit Application # PR14788: Technical Assessment Report, Britannia Mine Remediation Project, Britannia Beach, B.C. submitted to the BC Ministry of Water, Land and Air Protection. May 12, 2004.

Golder (Golder Associates) 2005. Groundwater Management System- Commissioning and Optimization. Submitted to EPCOR. May, 2005.

Golder (Golder Associates) 2006. 2005 Jane Basin Waste Disposal Documentation Report. Technical Memorandum. February 9, 2006.

Golder (Golder Associates) 2009. 2008 Data Report: Britannia Mine Environmental Monitoring. Submitted to the BC Ministry of Agriculture and Lands. February 23, 2009.

Golder (Golder Associates) 2011. 2010 Data Report: Britannia Mine Environmental Monitoring. Submitted to the BC Ministry of Natural Resource Operations. February 28, 2011.

Golder (Golder Associates) 2013. Britannia Mine Remediation Project, Quarterly Summary Progress Report No. 144. April 1 to June 30, 2013. Technical Memorandum.

Hagen, M., McCandless, R., More, B., & Colodey, A. 2004. Nearshore Contaminated sediment Investigations at Britannia Beach, British Columbia. Environmental Protection Branch, Environment Canada. Pacific and Yukon region. Regional Program Report 03-06. February, 2004. 63 p.

Price W.A., Schwab, T., Hutt, N. 1995. A Reconnaissance Study of Acid Mine Drainage at the Britannia Mine. Prepared for the BC Ministry of Energy, Mines and Petroleum Resources, Victoria, Canada. 129 p.

O’Hara, G. 2007. Water Management Aspects of the Britannia Mine Remediation Project, British Columbia, Canada. Mine Water and the Environment: Technical Communication. 26:46-54.

O’Hara, G. & Azevedo, B. 2008. Clearing the Water at Britannia Mine. Golder Associates, Mining Environmental Management, April, 2008.

SRK (SRK Consulting) 1991. Evaluation of ARD from Britannia Mine and the Options for Long Term Remediation of the Impact on Howe Sound. Prepared for Ministry of Energy, Mines and Petroleum Resources B.C. Acid Mine Drainage Task Force (BCAMD) 3.31. November, 1991. 150 p.

SRK (SRK Consulting) 2002. Britannia Mine Remediation, Initial Slug Test Report. Prepared for the BC Ministry of Water, Land and Air Protection. June 2002. 29 p.

SRK (SRK Consulting) 2003a. Britannia Mine Remediation Hydrologic Evaluation. Mining and Hydrogeology CLM02-18. Prepared for the BC Ministry of Water, Land and Air Protection. March 2003. 43 p.

SRK (SRK Consulting) 2003b. Britannia Mine Remediation Geochemistry and Watery Quality of the Mine Workings. Prepared for the BC Ministry of Water, Land and Air Protection. February, 2003. 53 p.

SRK (SRK Consulting) 2003c. Assessment of Surface Water Diversions in the Jane Basin and Victoria Glory Hole Catchments. Prepared for the BC Ministry of Water, Land and Air Protection. June, 2003. 29 p.

URS 2002a. Britannia Contaminated Site Investigation, Tier 1 Ecological Risk Assessment Fan Area: Britannia Mine Site, British Columbia. Prepared for the BC Ministry of Water, Land and Air Protection. June 27, 2002. 70 p.

URS 2002b. Britannia Contaminated Site Investigation, Fan Area Human Health Risk Assessment: Britannia Mine Site, British Columbia. Prepared for the BC Ministry of Water, Land and Air Protection. July 31, 2002. 46 p.

URS 2003. Britannia Contaminated Site Investigation, Additional Areas Tier 1 Ecological and Human Health Risk Assessment: Britannia Mine Site, British Columbia. Prepared for the BC Ministry of Water, Land and Air Protection. June 6, 2003. 56 p.

Vos R.J. & O’Hearn, T.A. 1993. Use of Zeolite to Treat Acid Rock Drainage from the Britannia Minesite. Proceedings of the 17th Annual British Columbia Mine Reclamation Symposium, Port Hardy, BC, 1993.

Leave A Comment

You must be logged in to post a comment.