Multi-layer soil cover

Henna Punkkinen, Markku Juvankoski, Tommi Kaartinen, Jutta Laine-Ylijoki, Elina Merta, Ulla-Maija Mroueh, Jarno Mäkinen, Emma Niemeläinen & Margareta Wahlström, VTT Technical Research Centre of Finland Ltd, P.O. Box 1000, FI-02044 VTT, Finland.

Introduction

The main function of a soil cover is to inhibit the influx of atmospheric oxygen and to limit the infiltration of meteoric water to the underlying reactive mine waste. Also upward movement of oxidation products or process water constituents is controlled when cover is used. Cover construction prevents direct contact with the waste material; covering isolates and stabilizes the waste and thus mitigates for example the generation of acid mine drainage and metal leaching. (e.g. MEND 2001; 2004; 2012, INAP 2003, Mylona et al. 2007) Engineered multi-layer soil covers for preventing acid mine drainage became widely used in the 1990s (INAP 2009).

Description of the methodology

A multi-layer soil cover is composed of two or more soil layers that are constructed with natural granular earth materials and placed on top of the mine waste. Different cover types are ranging from relatively simple two layered structure to complex covers containing several different layers and soil types. At least clays and tills, lake-bottom sediments, loess, silty sands, sand, gravel, riprap, and bentonite materials can be used for soil cover construction (MEND 1994, MEND 2004). Construction materials can also include mine rock (INAP 2009); it is possible to use inert-like tailings for covering reactive mine wastes as a part of the soil cover structure (MEND 1999).

A typical cover thickness varies between 0.3 and 3 meters (European Commission 2009). It is good to notice that the required soil masses for cover construction are enormous. For example, a cover thickness of 1.5 m means that 15 000 m3 of soil is needed to cover one hectare area of mine wastes.

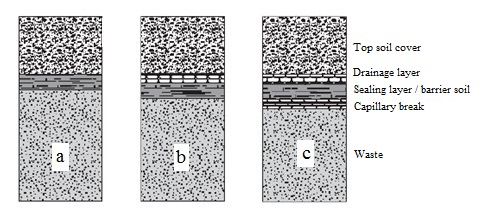

Figure 1 describes three different multi-layer soil cover designs with varying structural complexity. Example a) includes fine-textured compacted sealing/barrier layer (e.g. clay or clayey till) that maintains high moisture content to diminish oxygen transport, and unspecified top soil cover containing comparatively loose material, such as till. In Europe, the thickness of the top soil cover usually varies between 0.5-1.5 m, depending on climatic conditions, local flora and fauna, and the characteristics of the material used. In example b) a drainage layer is added on top of the sealing layer. The function of the drainage layer is to lower the hydraulic gradient and further reduce the infiltration. A coarse-textured layer under the sealing layer in example c) is called a capillary break. Capillary break inhibits dewatering by capillary transport downwards and the potential migration of dissolved harmful substances upwards. Also vegetation cover (e.g. grass) is usually applied on top of the top soil cover to prevent erosion. In addition, geotextiles can be used to prevent mixing of different layers. (European Commission 2009, INAP 2009)

Figure 1. Alternative options for soil cover design (adapted from European Commission 2009).

In humid climates, multi-layer cover structure usually includes capillary break on top of the waste material, compacted sealing, and a layer for vegetation roots. The structure may also include a capillary barrier system (INAP 2009), where a fine-textured soil layer is “sandwiched” between coarse-textured layers. The aim of the capillary barrier is to keep the fine grained layer continuously at or near saturation and thus reduce oxygen ingress. The barrier also reduces evaporation from the fine-textured layer. In addition, a control on net infiltration to the underlying waste can be provided. More detailed information about the performance of capillary barrier can be found in the literature. (e.g. MEND 2001, Mylona et al. 2007, INAP 2009) A capillary barrier system example is presented in Figure 2.

Figure 2. A capillary barrier system (adapted from Mylona el al. 2007).

Case studies are presented by:

- Mylona et al. 2007: Multi-layer soil cover structure was used to cover uranium tailings ponds in Pécs, Hungary. Two cover types were used; a cover with loess layers as storage and protection layers and clay as sealing layer, and a cover with loess storage and protection layers, sand drainage layer, and clay as sealing layer.

- Ayres et al. 2007; 2012: In Whistle mine in Ontario, Canada a backfilled mine pit was covered with multi-layer cover consisting of sand and gravel levelling layer (provides foundation for the geotextile, also a capillary barrier), geotextile (separation fabric), compacted clay (barrier layer), sand and gravel on top (protective layer/substrate for vegetation), and thin topsoil layer. Also a monitoring system was installed during the cover construction.

- MEND 2004: MEND report 2.21.4 presents case studies in which different types of cover systems for waste rocks and tailings are used, focusing on their design, construction and performance monitoring.

Appropriate applications

Multi-layer soil covers are suitable for covering sulphide bearing waste rocks and dewatered tailings. For example, a case study presented by MEND (2004) found this cover type to work effectively in reducing oxidation of sulphide containing mine wastes. Soil covers can also be used to control radon emission from uranium mine wastes.

Table 1 presents the most important advantages and disadvantages linked to the use of multi-layer soil covers.

Table 1. Advantages and disadvantages of multi-layer soil covers (e.g. MEND 2001; 2004; 2012, INAP 2003; 2009, Mylona et al. 2007, European Commission 2009).

| Advantages | Disadvantages |

|---|---|

| Suitable cover materials may be available near the site. | Oxygen influx into mine wastes can increase if the water content in the cover has become lower. |

| It may be possible to utilize soil materials that are removed around and top of the ore deposit. Also tailings may be utilized. | If the low hydraulic conductivity layer is dewatered, a risk for cracks will become higher, thus leading to increased oxygen transport. |

| Cover isolates and stabilizes the waste, and prevents contact with the waste material. Stabilization prevents dusting, and protects wastes from erosion and frost. | Soil covers may be vulnerable to vegetation, climate, erosion, animal, and human activity (including vehicle traffic): water permeability of infiltration barriers may increase with time, long-term maintenance may be required. |

| Covering stabilizes wastes also physically thus improving slope stability. | High transportation costs, if suitable materials are not available near the site. |

| Provides a substrate for vegetation. | Long term durability of geotextiles (if used) is unsecure. |

| Contaminant releases can be more efficiently controlled through better quality of runoff waters and infiltration control. | Cover does not stop infiltration; although acid generation is reduced, it may not stop entirely. |

Cover effectiveness relies on the appropriate moisture content in the covering layers (European Commission 2009). The suitability of the method is strongly dependent on climatic and hydrologic conditions of the site. As the active compacted layer needs to maintain its moisture content at or near saturation, multi-layer soil covers are only suitable for areas where precipitation is high enough. (MEND 2004)

Performance

In the long run, all dry cover systems must endure the effects of climate, hydrology, human activity, animals, vegetation, and the settlement of underlying material (INAP 2009). These processes may cause mixing of layers, cracking, or other possible discontinuities in the layer structure (European Commission 2009). Especially clay layers in are prone to cracking and other deterioration and due to these issues the long term performance of the covers consisting compacted clay layers has been questioned (MEND 1994). Seasonal climatic variations (e.g. freeze/thaw and wet/dry cycles), root penetration, erosion and burrowing may cause channel development (e.g. fissures, cracks and fractures) as well as other deterioration processes in the compacted clay material, and have effects on the cover functionality (MEND 1994, INAP 2003). According to INAP (2009) cover design with compacted clay rich barrier layer will function best in wet tropical and temperate climates. The use of this cover type has many suitability issues related to their use in cold climates, and clay materials may also be poorly available. Cover structure consisting of compacted clay layer should only be used in areas where the depth of freezing is known. Also certain thickness of the layer on top of the compacted clay layer is required to prevent the clay layer from freezing. (MEND 2012)

All cover types will eventually need some maintenance. Maintenance can be required for example to prevent the establishment of shrubs or trees whose roots could harm the cover performance; maintain the moisture content on the compacted layer (MEND 2004), and erosion repairs. Also the consequences of settlement, sediment transport and physical degradation may require maintenance, although these aspects are seldom acknowledged upfront. (Rykaart & Caldwell 2006)

If the complexity of the structure is increased, it usually means that also cover system performance is enhanced (Note: this is not automatically true for all climate conditions). However, increased complexity usually means that also the construction costs are higher, the structure is more complicated to construct (INAP 2009) and more skill for construction is needed. Also, availability of the cover material (possible transportation costs), size of the construction fleet, size of the waste facility to be covered, and thickness of the layers affect to the cover construction costs. In addition, if mining company carries through progressive reclamation instead of post-closure reclamation the costs may vary. (Rykaart et al. 2006)

It is obvious that the costs of cover construction are highly site specific. Cost estimates given in literature range at least from $35 000/ha (relatively simple barrier-type cover system consisting of 300 mm of loose vegetated till over 500 mm of compacted till) (Wilson el al. 2003) to $500,000/ha (multilayer complex infiltration reducing soil covers) (Rykaart et al. 2006). However, most multilayer covers cost at least $100 000/ha (Aubertin 2002, cited by Rykaart et al. 2006). According to Robertson & Shaw (undated) costs for complex covers containing multiple soils usually range in $20-30/m2 or $0.33-0.50/tonne waste rock.

Design requirements

Cover design is always a site-specific process, which depends on the climatic conditions, availability of materials, costs, waste characteristics, sensitivity of the surrounding environment etc. (Mylona et al. 2007) and no international standards for designing soil covers exist (Rykaart et al. 2006). Key factors to consider in the design of different types of soil covers include (e.g. MEND 2001; 2004, INAP 2009, Wahlström et al. 2009):

- Climate at the site (e.g. wetting, drying, freezing, thawing)

- Reactivity, type (tailings, waste rock), and performance (e.g. surface settlement) of the waste material

- Geotechnical, hydrologic, and durability properties of possible cover materials (e.g. stability, deformations, bearing capacity, frost protection, erosion protection, water permeability, prevention of drying, hydraulic conductivity)

- Hydrogeological setting of the waste storage facility, basal flow

- Long-term erosion, weathering, and evolution of the cover system

- Surface water flow and erosion

- Topography

- Availability of cover materials, suitable layer thicknesses

- Instrumentation needs to enable monitoring

- Construction quality control, quality assurance, and maintenance; and

- Design of landforms and final land use.

It is also important to notice the difference between sloping surfaces and horizontal surfaces. The intended performance of the structure may fail, if cover originally designed for horizontal surface is constructed on a slope. (INAP 2003, 2009)

Site-specific physical, biological, and chemical processes affect to the as-built performance and long-term performance of the cover, and the suitability of cover design should be evaluated in relation to them. (INAP 2003; 2009) Mostly physical and biological factors affect to the long-term performance of the cover structure (MEND 2001). There are basically two approaches for evaluating and monitoring cover performance; “macro” and “micro” monitoring. Micro monitoring monitors the performance of the actual cover system itself, whilst macro monitoring concentrates on water quality and flow measurements from seepage or overland flow that is discharged from mine waste facilities. (Rykaart et al. 2006) For example, a flux measurement through the cover is used for direct performance monitoring of the cover (MEND 2001). In many cases, lysimeters are used to directly measure infiltration though the cover system. Downstream water quality monitoring demonstrates the cover performance monitoring in a macro scale. (Rykaart & Caldwell 2006) Mylona et al. (2007) suggests that at least meteorological parameters, moisture storage changes, surface runoff, erosion, vegetation, and net percolation should be monitored when assessing the cover performance.

References

Ayres, B.K., Lanteigne, L., Smith, Q. & O’Kane, M. 2007. Closure Planning and Implementation at CVRD Inco’s Whistle Mine, Ontario, Canada. Mine Closure 2007, Santiago, Chile, October 16-19, 2007.

Ayres, B.K., Lanteigne, L., O’Kane, M. & Meiers, G. 2012. Whistle Mine Backfilled Pit Dry Cover Case Study – Performance Based on Six Years of Field Monitoring. Proceedings of the 9th International Conference on Acid Rock Drainage (ICARD), Ottawa, Ontario, Canada, May 20-26, 2012.

European Commission 2009. Reference Document on Best Available Techniques for Management of Tailings and Waste-Rock in Mining Activities, January 2009. Directorate-General JRC Joint Research Centre. Sustainability in Industry, Energy and Transport. European IPPC Bureau.

INAP 2003. Evaluation of the Long-Term Performance of Dry Cover Systems. Final Report. March 2003. Prepared by: O’Kane Consultants, Inc. OKC Report No 684-02.

INAP 2009. The GARD Guide. The Global Acid Rock Drainage Guide. The International Network for Acid Prevention (INAP). http://www.gardguide.com

MEND 1994. Evaluation of alternate dry covers for the inhibition of acid mine drainage from tailings. MEND Project 2.20.1. March 1994. Prepared by: SENES Consultants Limited. Mine Environment Neutral Drainage Program (MEND).

MEND 1999. Construction and Instrumentation of a Multi-layer Cover Les Terrains Aurifères. MEND Report 2.22.4a. Mine Environment Neutral Drainage Program (MEND).

MEND 2001. MEND Manual, Volume 4. Prevention and Control. MEND Report 5.4.2d. February 2001. Editors: Tremblay, G.A. & Hogan, C.M. Mine Environment Neutral Drainage Program (MEND).

MEND 2004. Design, Construction and Performance Monitoring of Cover Systems for Waste Rocks and Tailings. Volume 5. Case Studies. MEND Report 2.21.4. July 2004. Edited by: O’Kane Consultants, Inc. OKC Report No. 702-01. Mine Environment Neutral Drainage Program (MEND).

MEND 2012. Cold Regions Cover System Design Technical Guidance Document. MEND Report 1.16.5c. July 2012. Edited by: O’Kane Consultants, Inc. OKC Report No. 817/2-01. Mine Environment Neutral Drainage Program (MEND).

Mylona, E., Xenidis, A., Csövári, M. & Németh, G. 2007. Application of dry covers for the closure of tailings facilities. Land Contamination & Reclamation 15, 163-182.

Robertson, A. & Shaw, S. (Undated). Covers for mine waste disposal facilities. Robertson GeoConsultants Inc. & Mesh Environmental Inc. www.infomine.com

Rykaart, M. & Caldwell, J. 2006. State of the Art Review. Covers. InfoMine. www.infomine.com.

Rykaart, M., Hockley, D., Noel, M. & Paul, M. 2006. Findings of International Review of Soil Cover Design and Construction Practices for Mine Waste Closure. Seventh International Conference on Acid Rock Drainage (ICARD), March 26-30, 2006, St. Louis, Mo.

Wahlström, M., Laine-Ylijoki, J. & Vahanne, P. 2009. Materials for construction of top cover in landfills – Experience in the Nordic countries. TemaNord 2009:549.

Leave A Comment

You must be logged in to post a comment.